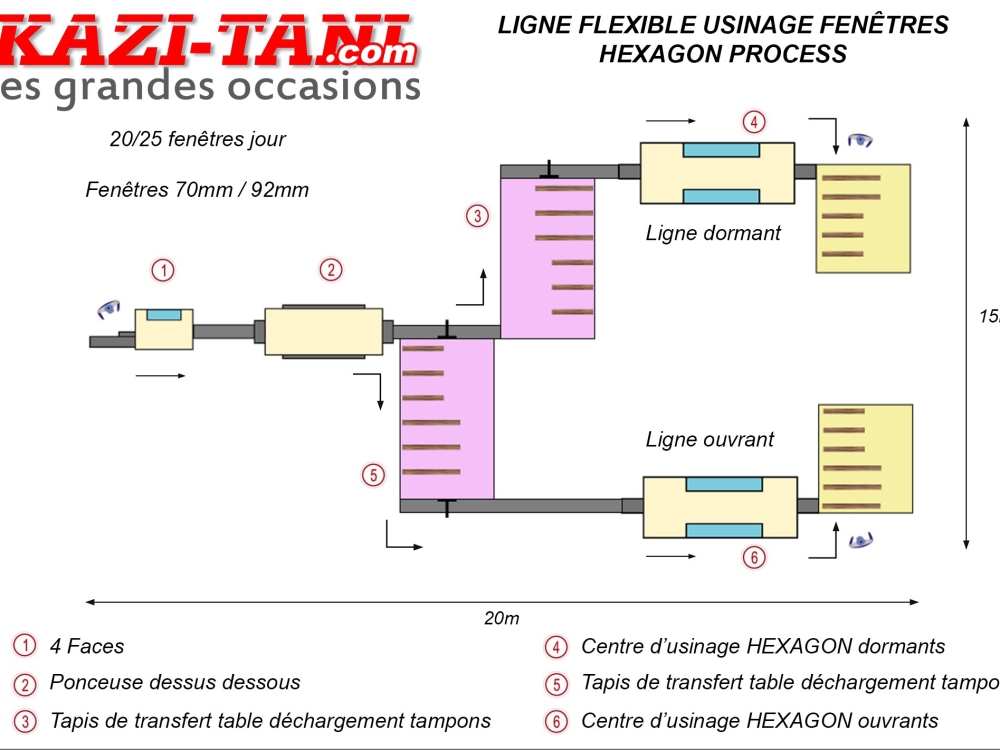

Flexible line for windows production HEXAGON - C2895 - C2895

Line composed of 6 elements:

Moulder SAC SUERI (n°1 on the plan):

4 shafts (lower planer, right router, left router, upper planer)

5m-25m/min

SAC SUERI top / bottom sander (No. 2 on the plan) :

Two groups sanding roller / face

Width 300mm

Top / bottom conveyor

2 Transfer conveyor with stand by loading table (n°3 and n°5 on the plan)

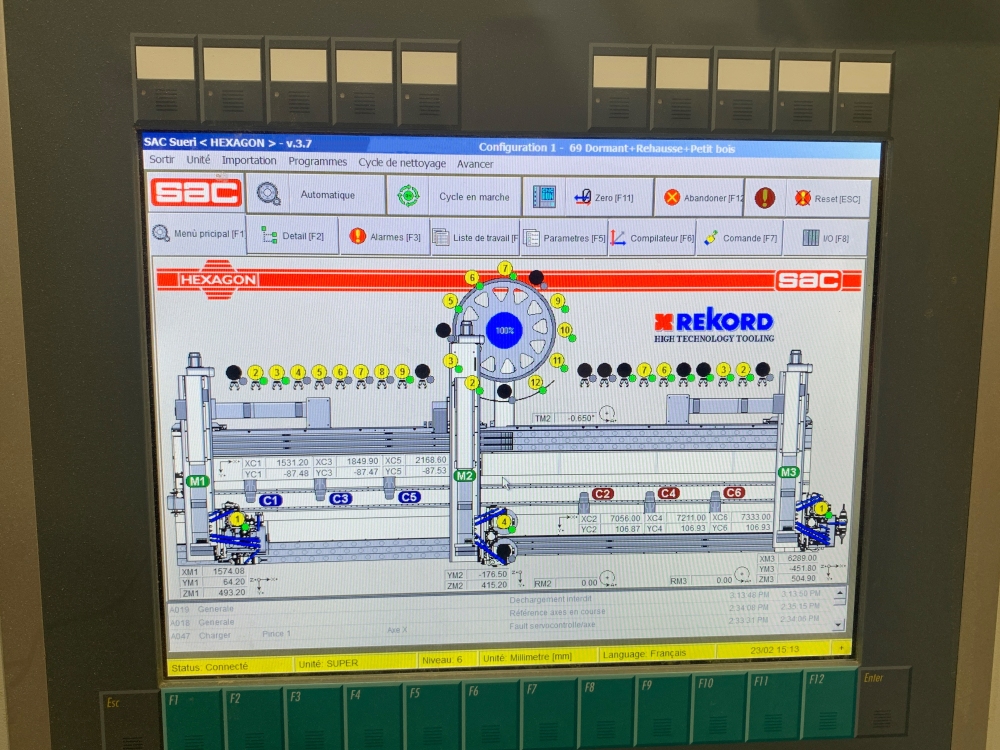

2 Machining centers for windows SAC HUERI HEXAGON (n°4 and n°6 on the plan)

3 axis machining centers

Machine dimensions : 7450 x 3445 x 2530

Useful dimensions: Length 2600mm, Height 120mm, Width h 210mm

Manual loading bench

6 parts taking clamps

Automatic system of parting exchange between the clamps

Wood chips evacuation conveyor

Part unloading

Integral safety cabin

Beckhoff control panel with industrial PC (15" color screen)

Composition:

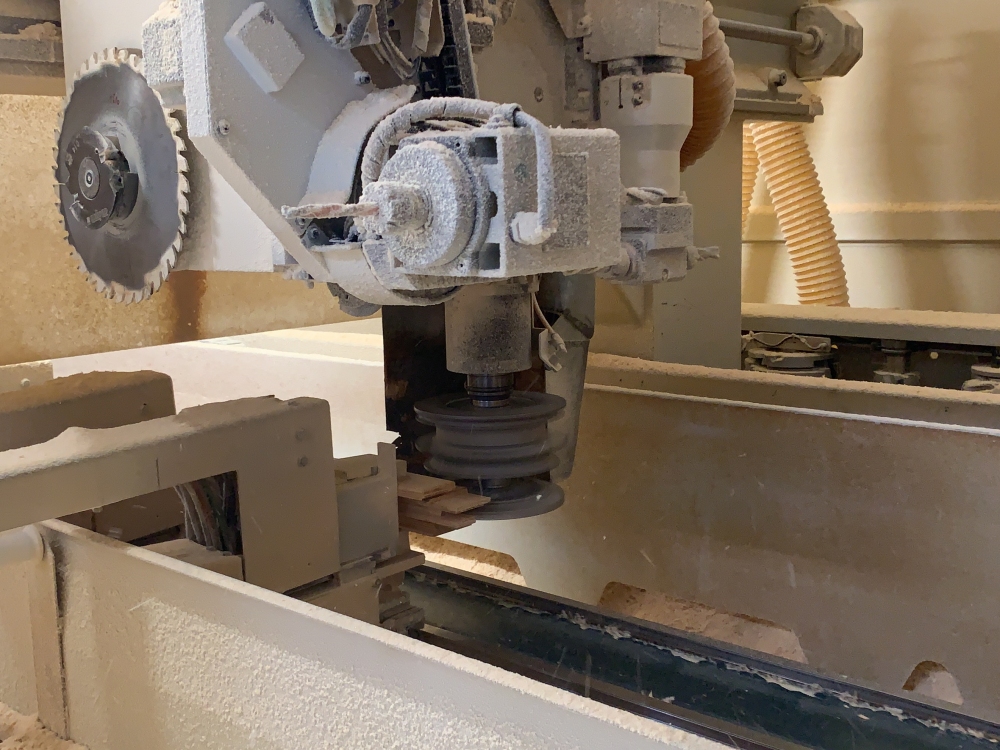

3 machining units :

Unit no. 1 (mobile left)

Linear tool magazine with 9 positions (HSK 63 F attach system)

Main electrospindle 11kW with tool exchange

Ø best profiling tool 200mm

Crosscut saw 3,1kW (max blade diameter 450mm)

2 spindle unit horizontal axis X 1,5kW

Tool holder ER25

Vertical unit 1,5kW

Attach system ER25

Unit n°2 (fixed central)

12-position rotary tool magazine (HSK 63 F attach system)

2 Electrospindles for tenoning 11kW with tool exchange

Max tenoning tool Ø 300mm

Max doveling size 115mm

Unit no. 3 (straight mobile)

Linear tool magazine with 9 positions (HSK 63 F attach system)

Main spindle 11kW with tool exchange

Max edging tool Ø 200mm

Glazing bead recovery unit 1,8kW (max blade Ø 200mm)

1 head spindle horizontal axis Y 1kW

Tool attach system ER25

1st and 2nd vertical spindle 1,5kW

Tool attach system ER25

Machining video link :