Double moulding edgebanding STREAM SB2 10.5 - C3086

Panel width : 240 mm to 1200 mm

Panel length : 240 mm to 3000 mm

Panel thickness : 10 mm to 60 mm

Band thickness : 0,3 mm to 3 mm

Pin inner axis : 500 mm

ENTRY / EXIT :

Transfer realised with special chains covered in stainless long lasting rubber

Entry pivoting guides adjustable depending on panel type

Closing device on above pressor to assure the pressing of the panel against the pins

Delaying device in entry for optimization of different width panel dimensions

Single part rigid structural longitudinal chassis

ADVANCE CHAIN :

Continuous speed tuning from 10 to 40 m/min by INVERTER CN direct numerical command

The stop pins are automatically adjusted in height by CN and can have : height/thickness 12- 18-23 mm from the chain level

Chain pin inner axis 500 mm

BELT PRESSOR

SOUNDPROOF CABINS

All machining groups inside the machine are surrounded by soundproof material Internal lighting

CN command placed at entry of the machine, fixed chassis side

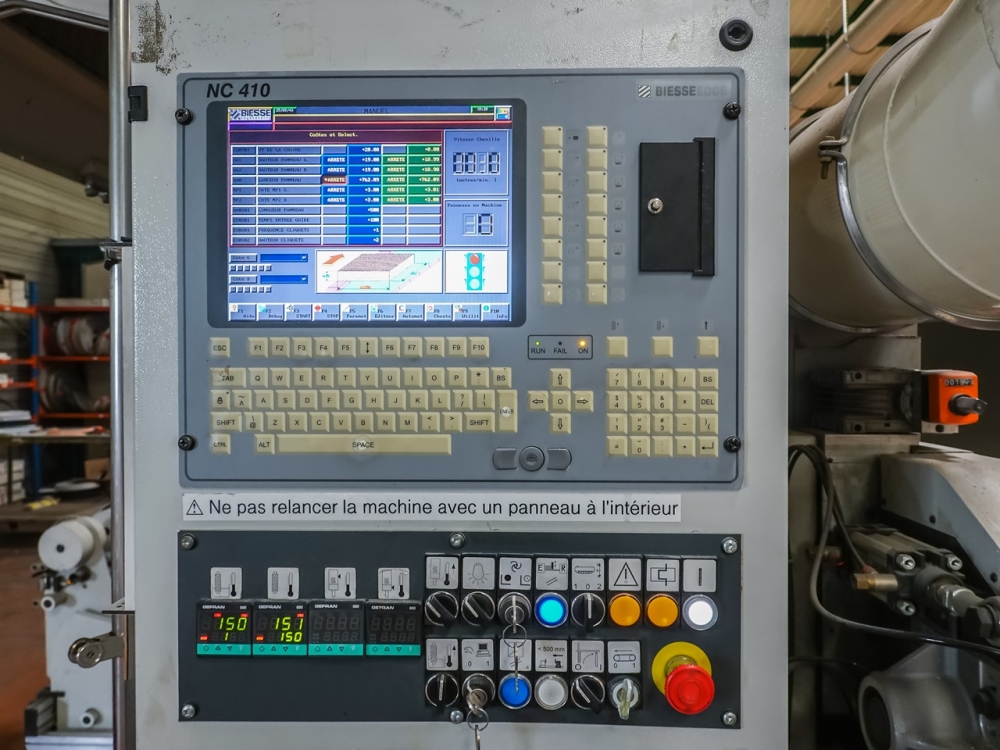

NUMERICAL CONTROL

Video interface

Positioning axis control

Chain advance speed tuning

Pressor height adjusting depending on panel thickness Automatic adjustment of band changing and band charger Moulding list management

Sequenced motor startup

Possibility of connection to a barcode reader

Module NC410

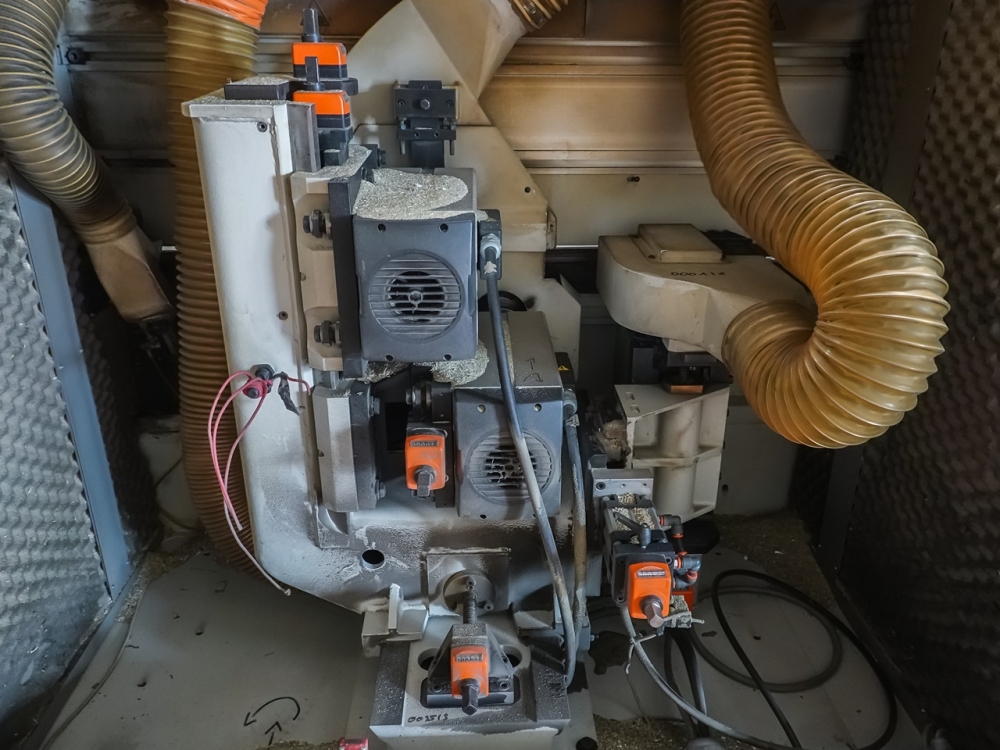

MILLING GROUP

Timed pneumatical anti shard action for transversal milling Tool rotation speed : 6000 rpm

Motor power : 5.8 kW

Tool Ø : 200 mm

DOUBLE SUPERPOSED SPLINTERS

Simultaneous displacement for thickness adjustment and independent adjustment vertical and horizontal

Cast iron bearing structure

Tool speed rotation : 6000 rpm

Motor power : 5.8 kW Tool Ø : 205 to 250 mm

EXTENSION MACHINE to 3200 mm

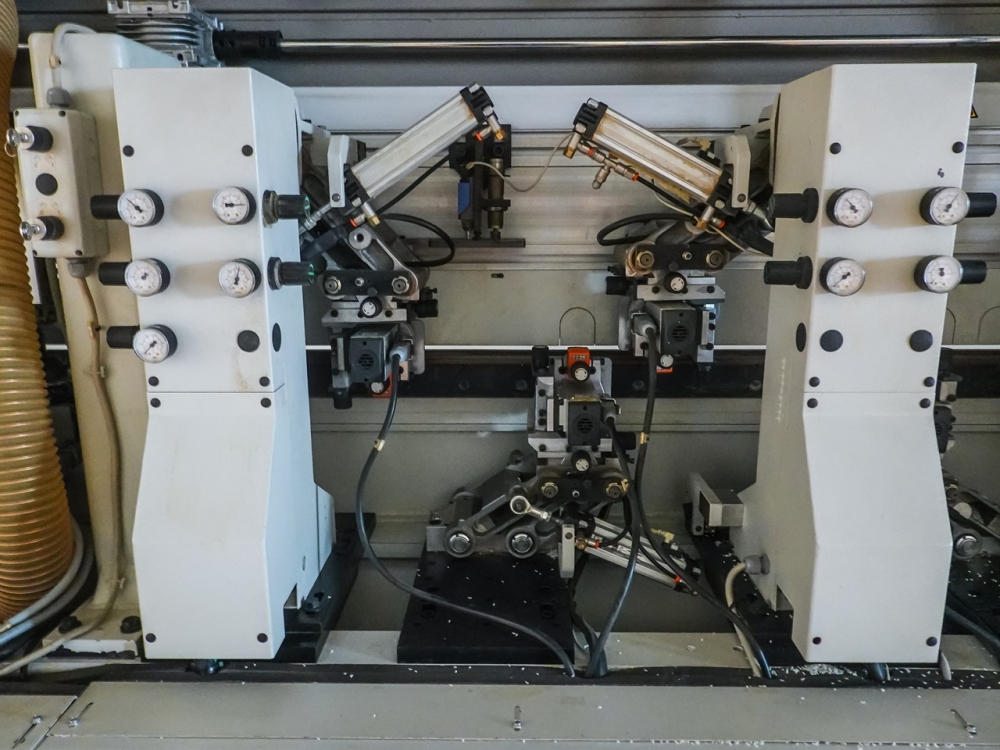

AUTOMATIC CENTRAL SUPPORT 10.5

This device allows support of parts that due to their dimensions or thickness can subdue central bending

Fully automatic activation

GLUING GROUP SP3

Straight bands in resin, melamine, ABS, PVC, PP EVA basis thermoplastic glue

Independent Teflon covered changeable glue tank Glue level sensor inside the tank

Glue input roller speed synchronized with the chain advance Breveted pre fusion device

Glue granule container (8kg)

Band presence detection device

Automatic band changing procedure

6 POSITION MOBILE BAND CHARGERS

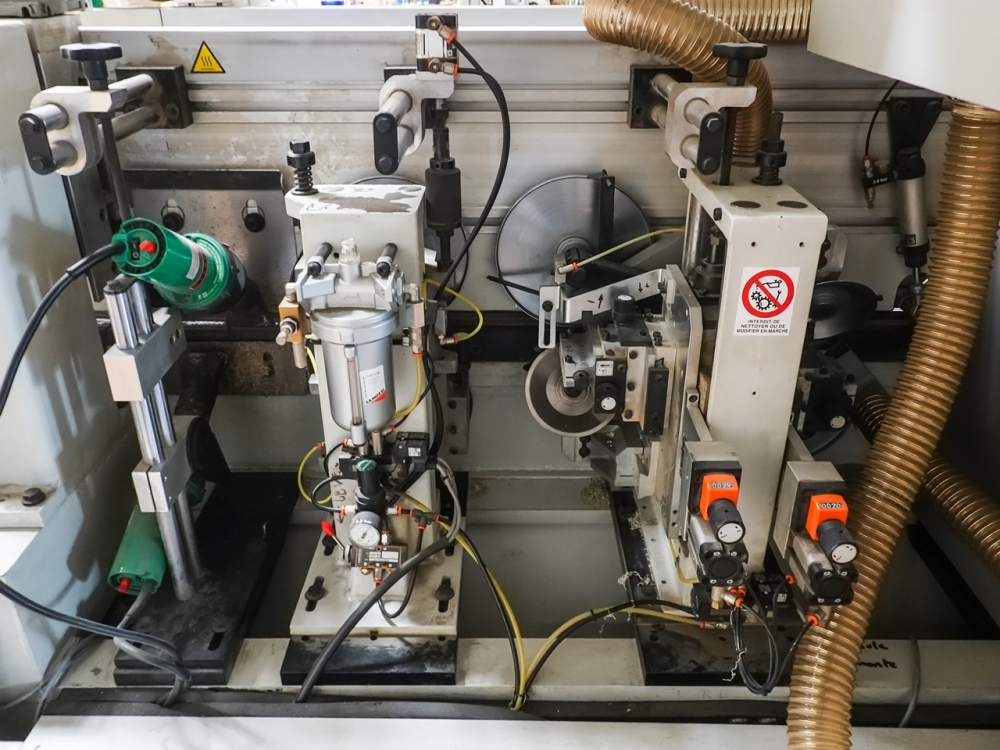

END CUTTING

End cutting unit for edge thicknesses up to 3 mm

Device for quick removal in stroke

Automatic exclusion of the unit when the motors are stopped

Speed : 12000 rpm

Panel projection : 35 mm

Edge thickness : 0.3 to 3 mm

Panel thickness : 10 to 60 mm

Interval between 2 consecutive panels : 350 mm

WHOLESALE TRIMMING UNIT

2 superimposed motors with horizontal axis

Automatic pneumatic exclusion of the group

Speed : 12000 rpm

Motor power : 1.3 + 1.3 kw

Panel thickness : 10 to 60 mm

Tool diameter : 80 mm

ANGLE TRIMMING GROUP

The adjustment of the position of the tool in relation to the material is automatic with predefined dimensions on 4 pre-adjustable in-line stops

The in-line stops are automatically selected by the control

Use on the MULTIPROFIL tool group to change profile/shape without replacing the tool

Tools are equipped with 20° chamfer and 1.5-2-3 mm radius

Speed : 12000 rpm

Motor power : 0.65 + 0.65 kw

Panel thickness : 10 to 60 mm

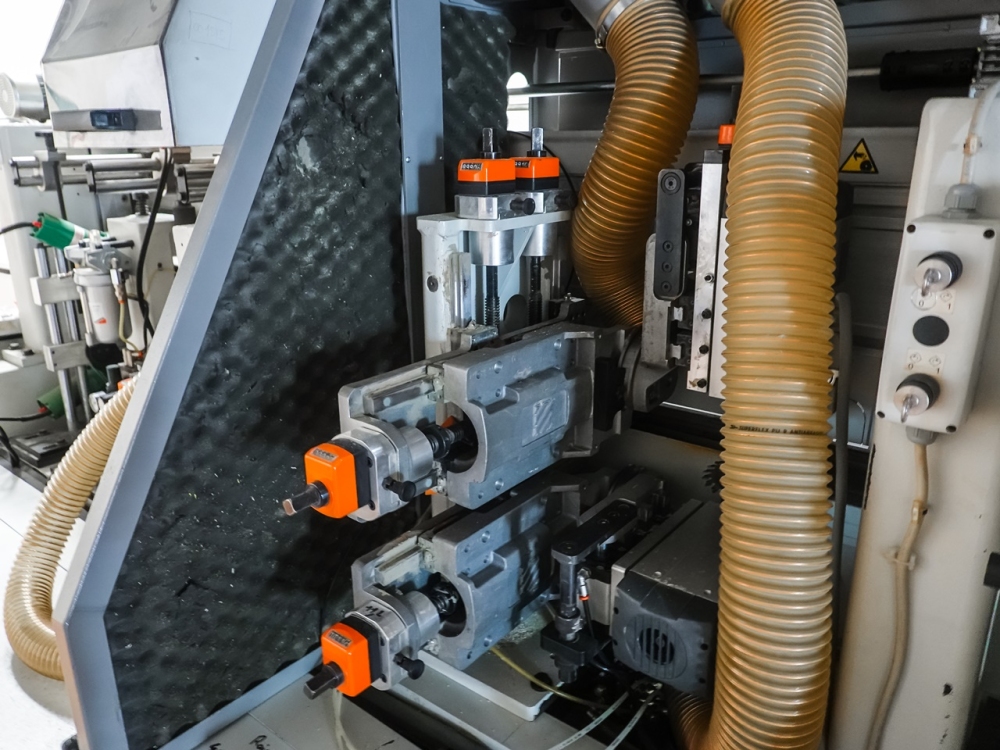

TOP / BOTTOM ROUNDING GROUP

Rounding copier for the upper and lower stops of the panel with oscillating movement for the continuation of the panel

Quick release system of the motor-holder groups

Automatic exclusion of the tool with stopped motors

Tool rotation speed : 12000 rpm

Motor power : 0.3 kw

Edge thickness : 0.3 to 3 mm

Radius with concave profile : 40 mm

Minimum distance between the tail of one panel and the head of the next (at 20m/min) : 500 mm

UNIVERSAL MILLING MACHINE

For the execution of profiles, grooves and rebates on the edge and on the plane of the panels with pneumatic intervention

Motor tiltable from 0 to 90° manually

Automatic exclusion group from the control panel

Speed : 12000 rpm

Motor power : 5 kw

Tool diameter : 125 mm

DOUBLE UNIVERSAL MILLING MACHINE

For the execution of grooves and rebates on the edge and on the plane of the panels with pneumatic intervention

The upper motor is manually adjustable from 0 to 90°.

The lower motor is fixed horizontal

Automatic exclusion of the groups from the control panel

Speed : 12000 rpm

Motor power : 5+5 kw

Tool diameter : 125 mm

EDGE SCRAPING UNIT

For the finishing of ABS/PVC/PP edges of high thickness with radial tools and horizontal and vertical copiers

Equipped with nebulizer for tool cleaning

Automatic exclusion from the control panel

Tool radius: 1 to 5 mm

EDGE HEATER

Allows to heat the edge of the panel during the passage of the latter to reactivate the original color when using PVC materials

GLUE SCRAPING UNIT

EDGE-CONTROL DEVICE

Electronic-mechanical device for the control of the edge length by means of shears at 40m/min

Minimum length of the edge to be applied: 350 mm

BAR FOR NARROW PIECES SB

Minimum width of panels: 35 mm

KIT FOR NARROW PIECES WITH THIN EDGES

It allows to work pieces with minimum width 70 mm, only in case of thin edge application

Minimum panel length 400 mm

PREDISPOSITION FOR INSTALLATION KIT PU GLUING