Slow grinder VOREMA VSL 100-30B

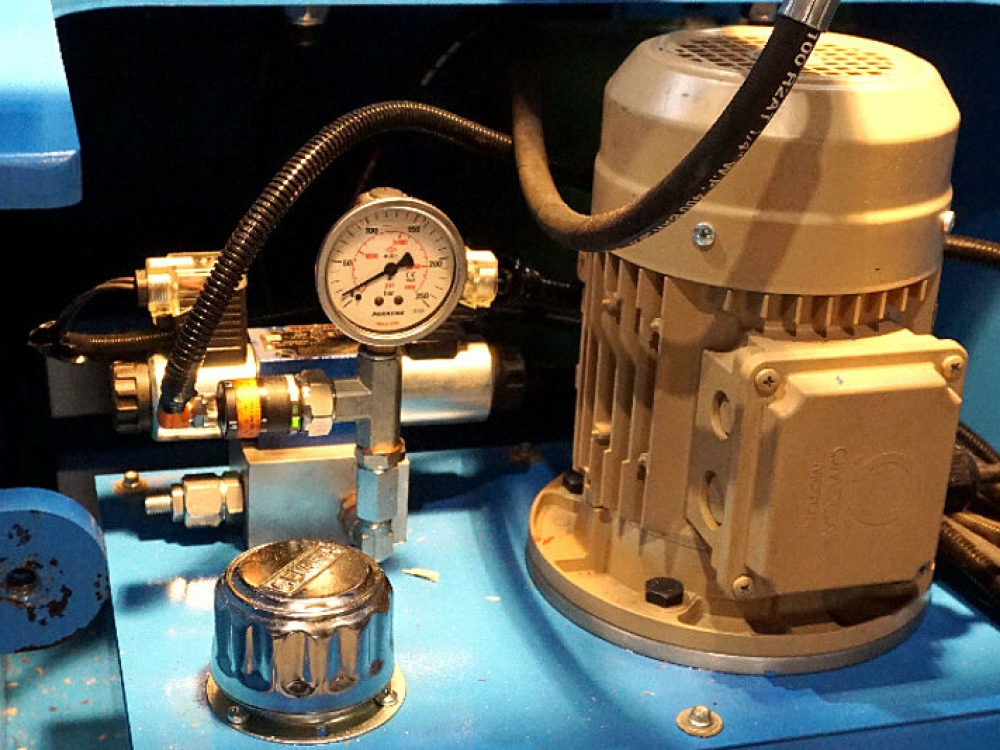

Motor power : 30 kW

Hopper dimensions : 1000 x 1200 mm

Hopper volume : 1.4 m3

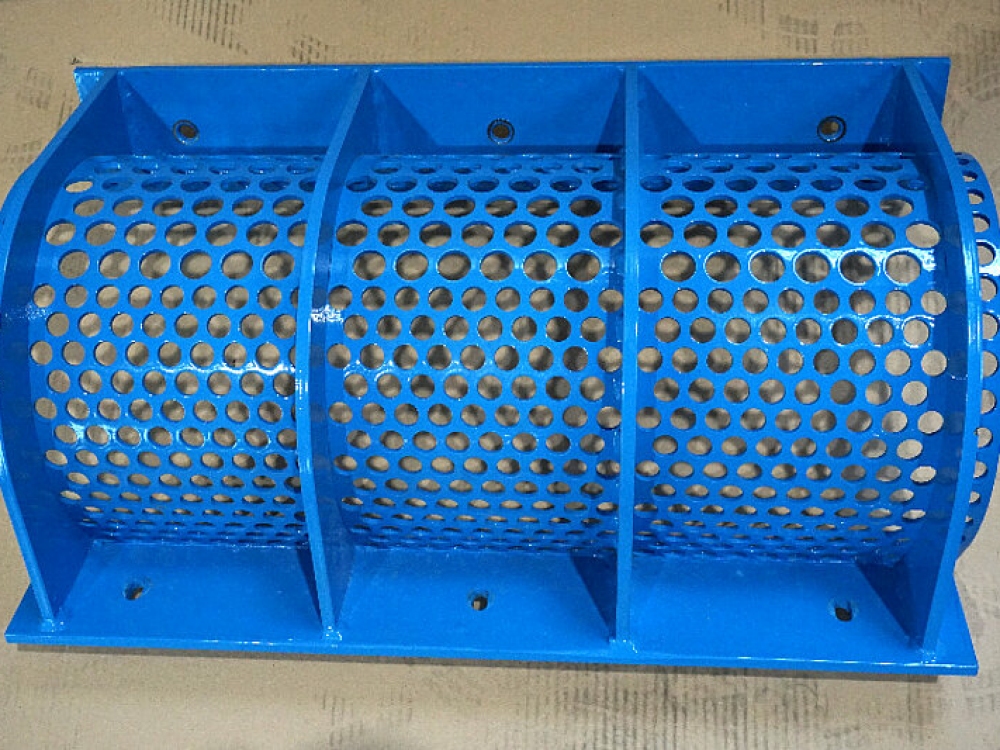

Rotor diameter : 352 mm

Rotor length : 1020 mm

Number of knives : 75

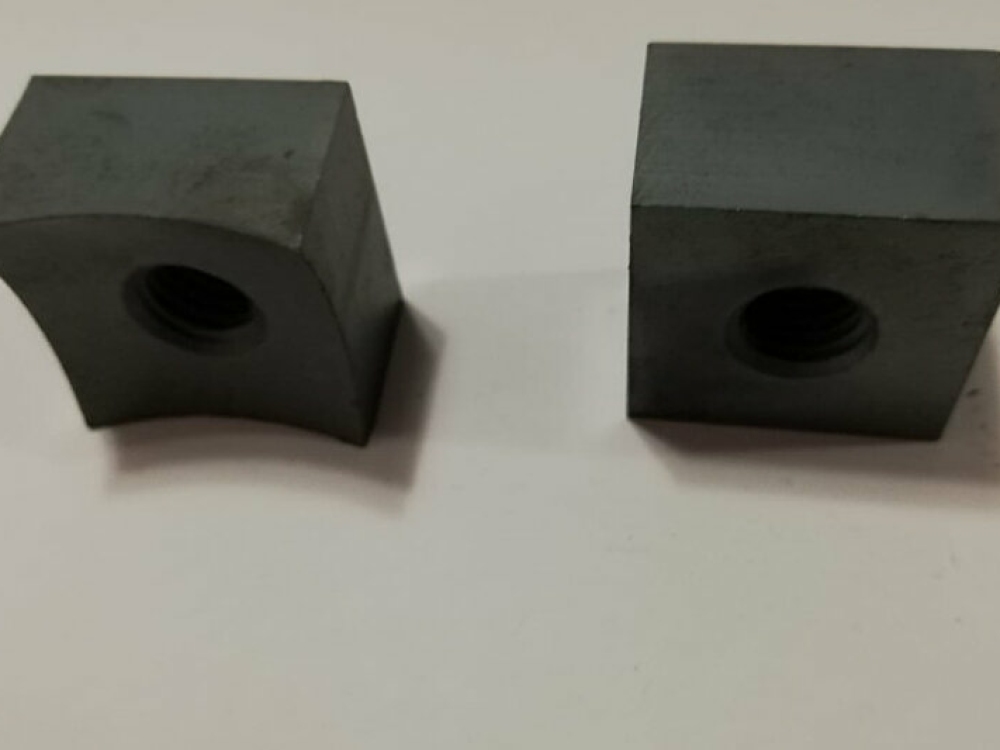

Knife dimensions : 30 x 30 mm

1 suction port Ø 250 mm

Options :

Magnetic separator Ø 250mm to be mounted (to be installed after the grinder) : 1232€ taxes excluded

VSL single-rotor shredder operating principle :

The material is fed into a hopper from above. A hydraulic feed pusher pushes the material to be crushed against the knife rotor, step by step, depending on the motor.

Shredding takes place between the rotating knives mounted on the rotor and a counter-knife attached to the machine frame.

Once shredded, the material is transported via a suction system, an extraction screw or a conveyor belt.

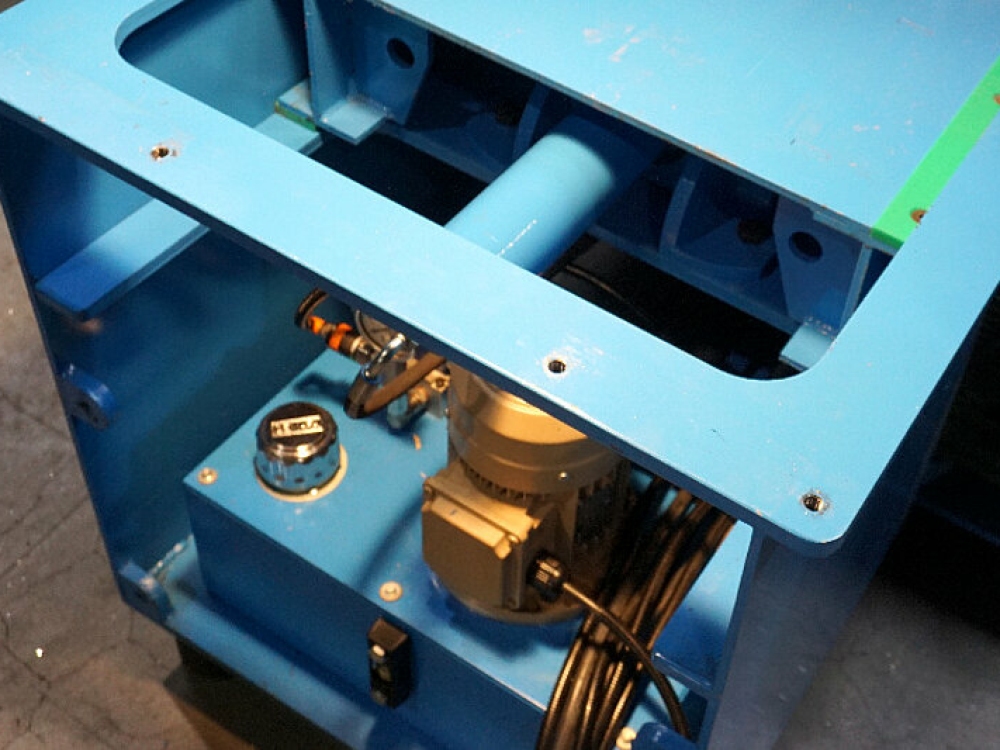

1) The pressure bar pushes the material towards the rotor shaft. When the motor's power consumption increases, the pusher stops; as soon as the energy consumption decreases, the pusher starts moving again and moves forward (step-by-step).

2) The cardanically-mounted hydraulic ram pusher moves forward with extreme regularity, ensuring high reliability of shredder operation.

3) The use of standard and concave knives in equal proportions ensures that our shredders have a high shredding capacity.

4) In each shredder, the screen perforations determine the size of the shred. In all cases, their size

is always tailored to the customer's specific application.

5) The hydraulic power pack and cardan cylinders are integrated into the machine body, avoiding any risk of damage.

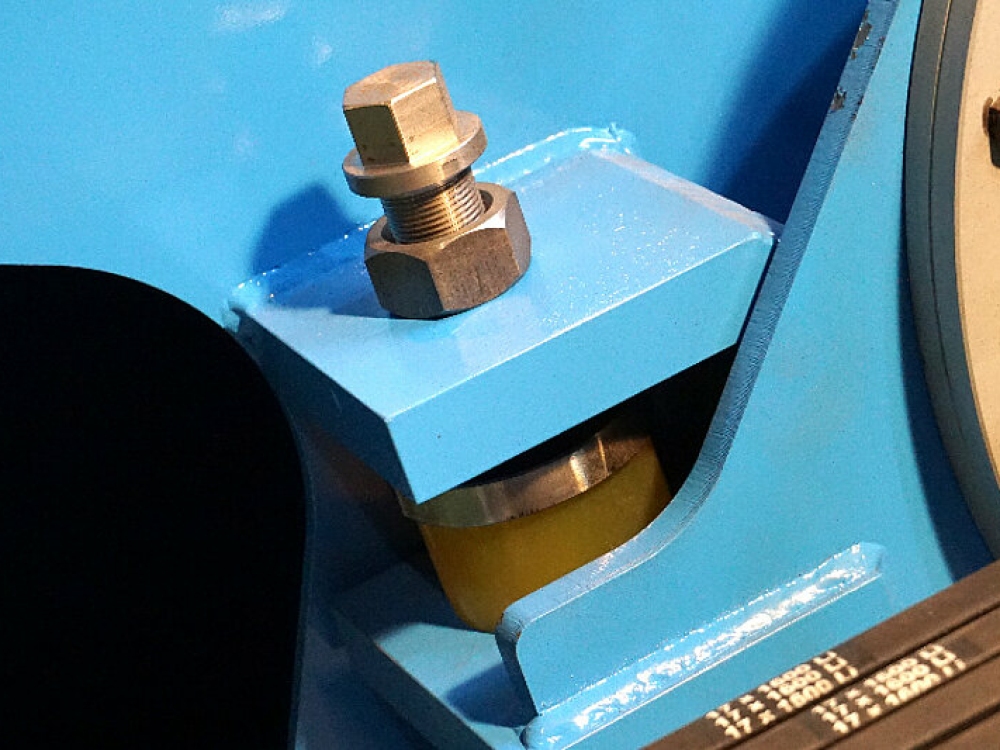

6) Damping of the transmission by a rubber buffer and decoupling of the transmission from the motor guarantee exceptional motor life.

Brand new machine, 2 years warranty