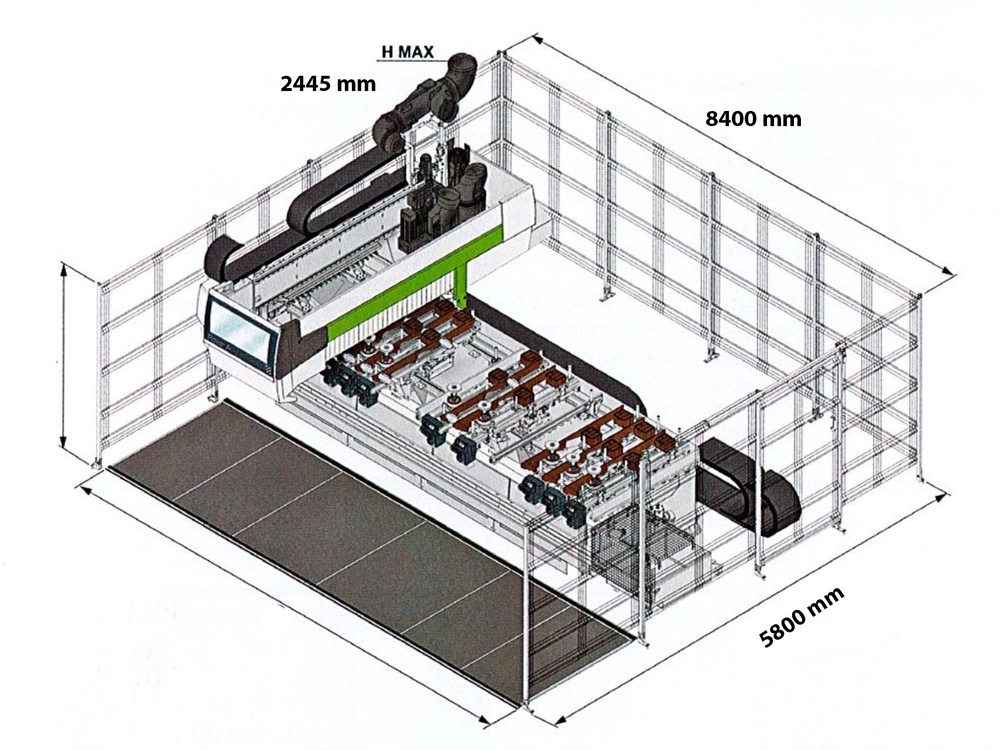

Machining center BIESSE Rover A G 2243 FT - C3181

Nesting machining center with full table

X axis travel: 4300 mm

Y axis travel: 2205 mm

Z axis travel: 326 mm

Electrospindle

3-axis spindle, 12 kW

HSK F63 chuck

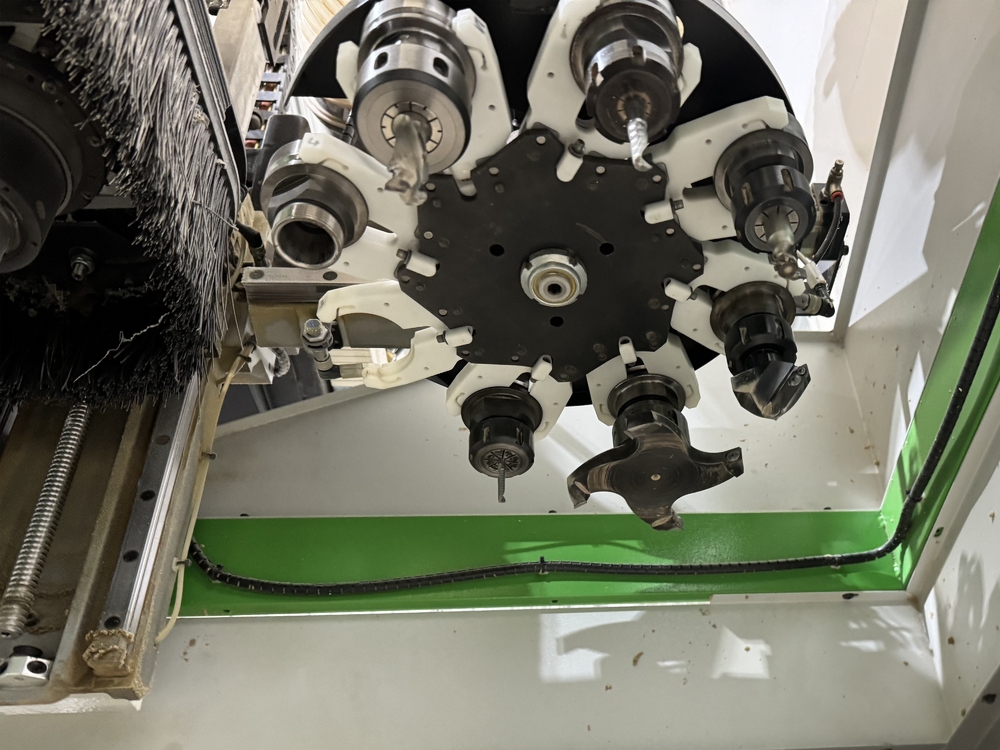

Revolver-type tool magazine, 8 tool holders

BH17L drilling unit

Vertical and horizontal drilling unit + grooving unit

10 vertical drill bits, 32 mm pitch (7 X-oriented and 3 Y-oriented)

6 horizontal drill bits, 32 mm pitch (2 X-oriented and 1 Y-oriented)

1 grooving blade, diameter 120 mm, for grooving in X (useful cut 25 mm)

Independent Z drilling unit to optimize machining times

9-area vacuum table with MDF martyr panel

Rear, front and side (left) reference stops

2 vacuum pumps 300 m3/h

Controls :

On Windows PC

BiesseWorks Advanced software machine version

Programming and optimization of drilling, cutting, milling, toolpaths and tool changes

Customized parametric macros

Network and/or USB file imports

3D part and toolpath simulator

Parametric programming of the workpiece

Martyr table surface program

Collision management

Tooling set and parametric cones supplied

2 BiesseWorks office version software keys supplied

This machine is available unless sold in the meantime

If you need spare parts, blades, knives other accessories (filter systems, compressor, etc.), we will be happy to help you.

After validation, the machine will revised, controled, and tested before packing for departure with a 3 months warranty.(**)

Lease financing offers can be studied on a case-by-case basis by our partner.

(**) please check the warranty contract